Markets, Regulations, and Food Safety

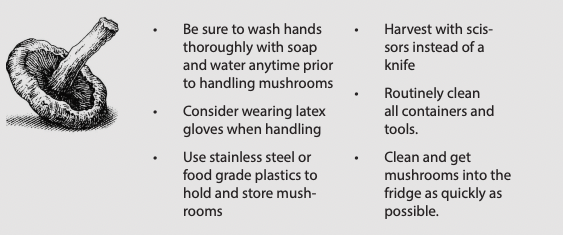

While many growers focus heavily on the technical aspects of production, it is the post-harvest handling and sales that counts in making for a profitable enterprise.

Growers can fetch a premium price for specialty mushrooms , provided they can maintain quality throughout the post-harvest process.

Anyone who is serious about making money with the sale of mushrooms should plan on devoting equal time to learning how to best grow high quality mushrooms as well as the multiple aspects of running a small farm enterprise.

Building a successful enterprise requires a few key steps:

1) Understanding the safe handling of product from harvest to market.

2) Following any relevant regulations for produce and food products.

3) Determining the most efficient market channels and developing sound financial planning for the enterprise.

Results from a 2021 survey of specialty mushroom growers around the USA offer an interesting glimpse into this growing industry. Click here or on the image to download the PDF and read more.

Key Points:

-

Demand for specialty mushrooms was high for many respondents, 64% of them reported higher demand for their mushrooms than they could supply

-

As a whole, respondents rely on farmers markets as the most important way to sell their mushrooms, accounting for 38% of mushroom sales. When combining all direct-to-consumer markets, a total of 71% of respondents' mushroom sales were made through direct-to-consumer markets.

-

We asked growers to rate how important they feel various mushroom characteristics are to their customers. Our respondents feel that mushroom quality is the most important characteristic to their customers, ranking it 4.6 out 5 (Figure 12). Respondents also rated being local as very important at 4.2 out of 5.

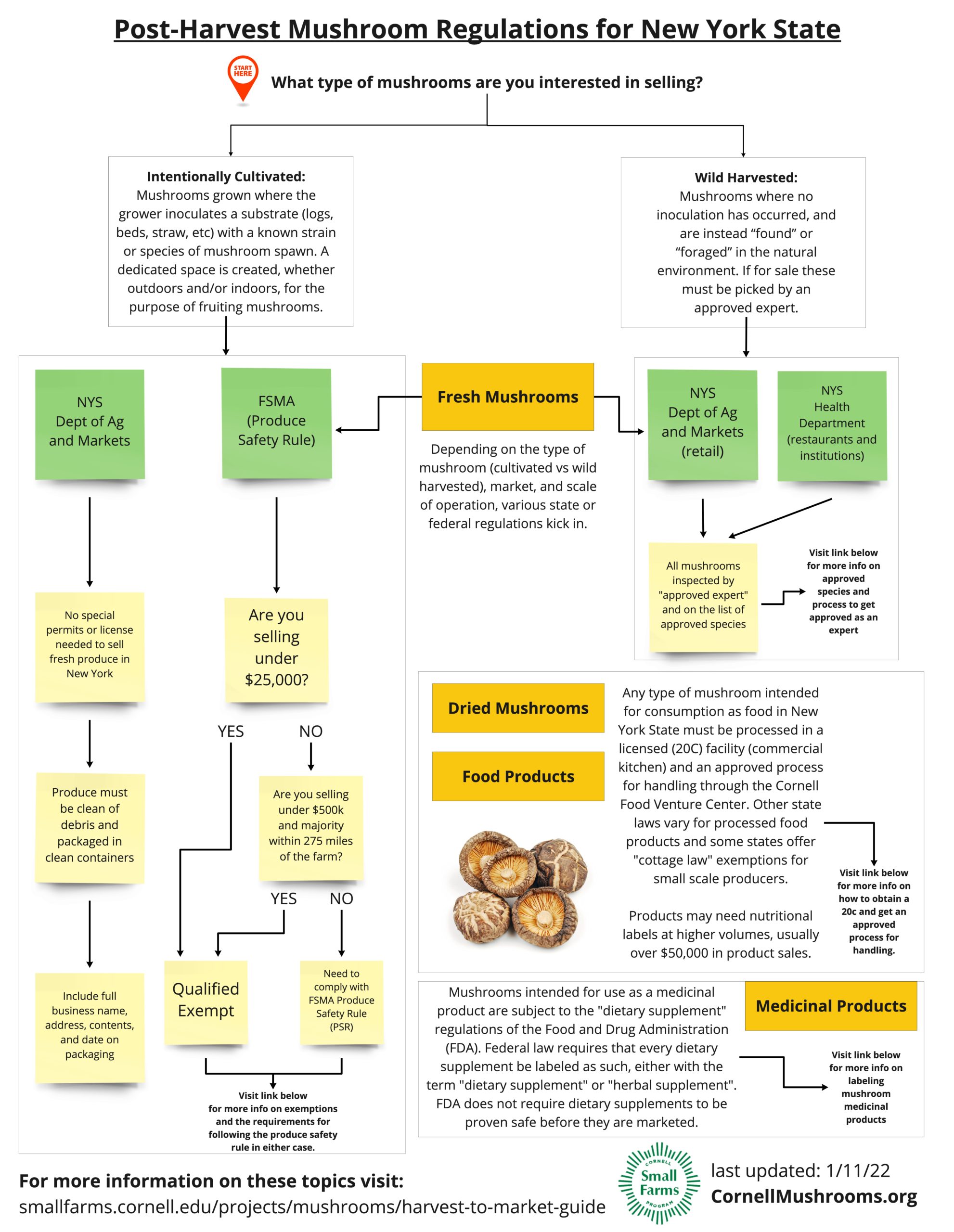

Navigating the Regulations

The image at right provides an overview of the regulations to consider in selling mushrooms. Note that this diagram is specific to New York State, so if outside of NY check with your state agency to learn more about who regulates various sectors.

Most states differentiate between "Intentionally Cultivated" and "Wild Harvested" Mushrooms for regulatory purposes. Generally, simply selling mushrooms you grow in a designated space as a fresh produce item means you can sell with little or no regulation, at least a smaller scale. As your enterprise scales, you are potentially liable to follow state and/or federal guidelines to ensure food safety.

Wild Mushroom sales generally require passing an exam to demonstrate your ability to properly ID mushrooms and the use of traceability in your labeling practices. Once you want to dry or otherwise process mushrooms you get into the need for a certified kitchen, at least in New York.

Explore the image and note that each of these sections is expanded in greater detail in our harvest to market guide, below.

Explore our FREE guide "From Harvest to Market" was informed and reviewed by multiple educators and growers in the specialty mushroom industry, providing a roadmap for new growers to get started. You can also download a free PDF of the guide here as well.

Section 1:

Post Harvest Handling

A. Food Safety & Sanitation (GAPS and FSMA Regs)

B. Harvest, Cleaning, & Storing

C. Grading

D. Weighing

E. Packaging & Labeling

F. Pricing

G. Guidance For Wild Mushroom Sale In NYS H. Dehydration

I. Value Added Products

Section 2:

Enterprise Planning

A. Mushroom Identification & Insurance

B. When Am I A Farm? C. Taxes & Ag Assessment D. Business Planning

E. Budgeting & Cash Flow

F. Record Keeping

G. Strategic Marketing/Channel Assessment H. Branding

I. Certification J. Final Thoughts