Chainsaw Safety, Part 4: Reducing the Risk of Chainsaw Kickback (Just say No to Kickback!)

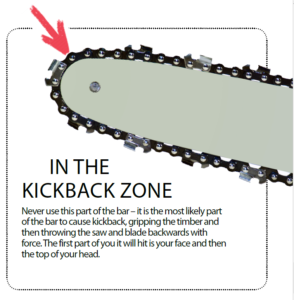

In the first three articles of this series on chainsaw safety we focused on having the right types of safety equipment when using chainsaws. It is imperative to have all of the right OSHA (Occupational Safety and Health Administration) approved safety features when you or your employees use chainsaws. In this article, we will look at how to prevent kickback injuries, one of the most common ways that chainsaw injuries occur. What is kickback? It happens when the top front tip of the chainsaw bar hits an object, and “kicks back”, oftentimes hitting the operator and causing either death or grievous bodily harm.

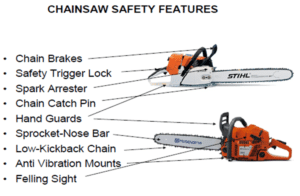

Select a chain saw that is equipped with kickback-reducing devices (e.g., chain brake, low kickback saw chain or reduced kickback saw chain) that are designed for the chain saw that you are using and meet OSHA standards. These devices will reduce but will not prevent kickback.

Watch the guide bar nose. Do not let it touch logs, branches, or the ground when the saw is running. The majority of chainsaw accidents come from

Run the saw at full power when cutting, and keep the chain sharpened to specifications (e.g. correct depth and angle). Matching the chain and bar for exact and correct pitch and gauge is imperative, and set depth gauges to manufacturer’s settings. Maintain correct chain tension as shown in the last edition of SFQ. Hold the saw securely with both hands. Have one hand on the handle bar and the other on the grip or trigger, and do not operate the saw left handed, as the blade will hit you directly with kickback if you do so.

Ensure that you have firm footing before starting to saw, and stand to side of the cutting path of the chain saw. Also, position yourself so that you are not near the cutting attachment when the chain saw is running. Knowing where the bar tip is at all times is crucial. Make sure the chain brake functions and adequately stops the chain. The stopping power of a chain brake can be greatly reduced by wear, or by oil, dirt or sawdust in the brake parts. DO NOT USE A CHAINSAW IF IT DOES NOT HAVE A CHAIN BRAKE! Sometimes installing a safety tip that covers the nose of the guide bar on the saw helps to prevent contact with the kickback zone. The tip must be removed for making bore cuts (pocket cuts) or for cutting wood thicker than the length of the guide bar. Always wear the required personal protective equipment!

As has been mentioned in previous articles, attendance at one of the “Game of Logging” sessions can provide you and your employees with the proper training in the use of chainsaws. Keep the tip of the moving bar away from any object!