Economic Report for Log-Grown Shiitake Mushrooms (2019)

This project report is supported by a grant from the USDA Specialty Crop Grant Program, and New York Farm Viability Institute, with additional support from Cornell Cooperative Extension. Originally Published in 2019.

What are Specialty Mushrooms?

Specialty mushrooms are defined by USDA as any species not belonging to the genus Agaricus (button, crimini, portabella). The most common specialty mushrooms are shiitake (Lentinula edodes) and oyster (Pleuterous ostreatus), which represent the second and third most produced in the United States (USDA, 2017). Demand for specialty mushrooms is rapidly rising, as consumers look to purchase more foods that are healthy, nutritious, and medicinal. United States per capita consumption of all mushroom species was only 0.69 lbs. in 1978, but by 1999, averaged 4 lbs. per capita.

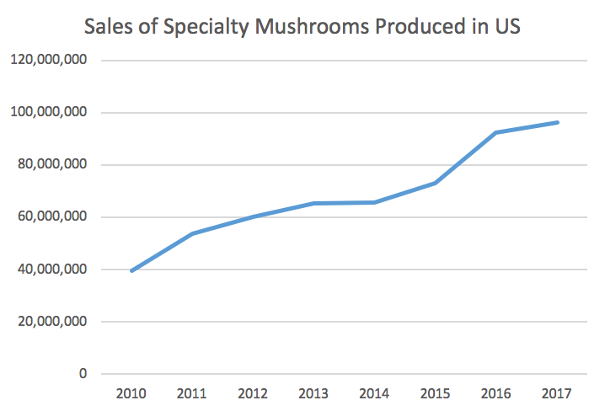

Figure 1: Sales of Specialty Mushrooms in USA (Source: USDA:NASS)

Mushrooms are nutritious, ranging from with twice the protein of most vegetables and containing all the essential amino acids for humans (Chang, 1980). They serve as an alternative protein to animal sources and also provide dietary fiber and minerals with no fat (Shah, 1997). Some report mushrooms to be more satisfying to consumers than meat proteins (Hess, 2017). Mushroom intake is positively associated in diets with a higher intake of nutrients and a higher quality diet (O’Neil, 2013).

In addition to the nutritional value, both shiitake (Mizuno, 1995) and oyster (Patel, 2012) offer an impressive array of medicinal properties including antiviral, antimicrobial, anti-inflammatory, immune modulating, and more.

Market Demands in US

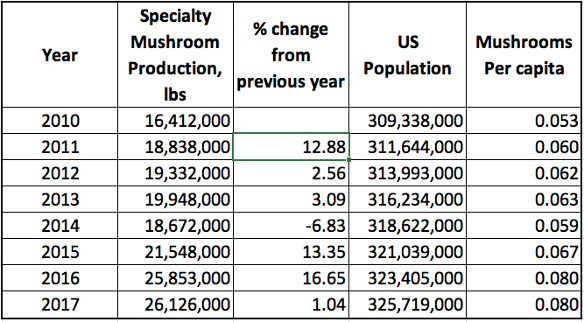

Sales have increased with demand (Fig. 1). In 2017, production of specialty mushrooms, grew by four percent from 2016 levels to 25.4 million pounds with a sales value of $96.2 million. While this represents a 9.6% increase from the previous year, there is still a high level of demand not being met. In 2017, specialty mushroom growers produced 26.1million pounds — a 5.5% average increase over the last five years. Yet, this averages 0.08 lbs produced per capita (Figure 2), compared to the national average of 4lbs/per. This production bottleneck is partially due to lack of growers. In 2017, there were only 226 growers commercially producing specialty mushrooms the United States (USDA, 2017).

Figure 2: Production of Specialty Mushrooms in US

In a previous USDA-SARE sponsored national survey of shiitake growers, 89% of respondents indicated that demand consistently exceeded supply in their region (Mudge, 2011). A 2015 Chatham University study interviewed 23 Northeastern buyers who reported needing 7,075 pounds of shiitake (307 lbs. per buyer) annually to fulfill customer demand, but only 2,060 pounds (29% of demand) of locally-produced shiitakes were available for purchase. Seventy percent of these buyers expected demand for forest grown shiitakes to increase over next five years (Matthews, 2015).

Why Log-Grown Shiitake?

Within the specialty mushroom industry, Shiitake Mushrooms (Lentinula edodes) are a familiar and highly prized product. Most shiitake are currently produced indoors on synthetic “logs” made of sawdust and nitrogen supplements, usually agricultural byproducts such as seed hulls and husks.

Figure 3: Log Grown Shiitake on a farm in New York

Outdoor log production is more common historically in parts of China, Korea, and Japan. Compared with indoor production methods, log-grown shiitake offer the following benefits:

- Logs can be acquired as the byproduct of sustainable forest management and offer a viable option to utilize woodlands for income generation.

- The natural woodland environment eliminates the energy needs of indoor production to maintain ideal temperature, humidity, and light requirements for production

- Due to low infrastructure needs, start-up costs for outdoor production are lower when compared to indoor systems (provided you have access to land)

- Outdoor shiitake are often more robust in texture, flavor, and color compared to indoor systems

- Shiitake mushrooms make an excellent dried product that extends the shelf 6 – 12 months

- Given that over 60% of all land in New York is forested and 21% of farmland is wooded, there is great potential to utilize small diameter wood for mushroom production, which can support ecological forest stewardship

Production Economics

Research at Cornell University along with University of Vermont extension from 2002 – 2012 has confirmed that log grown shiitake can be cultivated on a wide range of species and conditions and is the best candidate for outdoor log-grown mushroom cultivation if reliability is desired along with good marketability and profit potential. More details on the results of this study can be found in this related article.

Costs per log:

.75 in spawn

.31 in wax

$3.68 in labor to inoculate

$8.32 in labor to manage

Labor per log:

12 min felling and hauling

25 min inoculate

12 min harvest pack

11 min market and sell

Yields

1/4 – 1/2 # per log each time you soak

8 flushes

4 lbs total

Sales

Growers can achieve $12 – 18 per pound, with averages ranging from $10 – $12 wholesale and $12 – $16 retail.

Most commercial scale operations start at around 500 – 1000 logs in production, which yields on average 20 – 50 lbs of shiitake per week, from June through October.

A template budget based on these numbers can be found here.

Figure 4: Shiitake Farmer in New York

2019 Project Grower Data

We completed a follow up survey of all 2018 and 2019 workshop participants in our Shiitake Viability project with the following results:

91 responses from 464 class participants (19.6% response)

41.25% are aspiring farmers

47.75% are beginning farmers (committed to farming, less than 10 years)

11% are established farms more than 10 years

95% reporting feeling compelled to pursue shiitake mushroom production

97.8% indicated our resources and support were helpful in improving their knowledge

After workshops, actions taken include:

82.4% inoculated logs

47.9% read and researched more

22.7% registered a farm business

33.3% completed our enterprise budget tool

Current Production:

37.5% have 10 – 100 logs in production

42% have 101 – 300 logs in production

9% have 301 – 500 logs in production

5.4% have 501 – 999 logs in production.

31.6% report an increase in farm income

Future Goals:

28.4% aspire to scale up to 500 logs

29.73% aspire to get to 1,000 logs in production

Major challenges cited for production include:

time

access to logs for inoculation

skilled labor to help

marketing

paperwork and certifications

consistent production

Success Stories

Darling’s tree farm is a 15-acre enterprise with a focus on choose and cut Christmas trees and wreaths. We saw shiitake production as a potential way to differentiate and provide income outside of our traditional three-week window of sales. While we have decades of farming experience, it is specific to fir trees. None of us had any experience with mushroom production.

We’ve benefited from the collective experiences gathered by Cornell Small Farm Program. The Best Management Practices helped us get started, the workshop and one on one meeting helped refine our practices and the log growing business network is continuing our learning. We are looking forward to next year’s harvest when we should see the results of these new and improved practices.”

– Jeff Darling

Figure 5: Shiitake Laying Yard in New York

We are Mariann and Richard Johnston, and we purchased our 174-acre farm just outside of Theresa, NY in 2013. The farm is comprised primarily of hay fields and pasture; we presently sell the hay and board local organic dairy heifers. Because we were looking for innovative ways to utilize our farm, the idea of a shiitake operation was appealing. As foresters, we also liked the idea of utilizing logs from forest improvement operations. There is no question that the advice and suggestions offered during the viability workshop and individual consultation (as well as email follow-ups) enhanced the success of our first growing season.”

– Mariann Johnston

Participating in the Shiitake Viability Project has helped me to develop a plan for commercial mushroom production, and to work that plan in with my larger life goals. I’ve spent the past four years dabbling in growing shiitake while working elsewhere, and until this year was maintaining 50-100 logs spread across several locations without selling much of what I produced. Joining the Shiitake Business Development Network this summer has allowed me to work out a realistic pathway to reach this goal. In particular, by prompting me to think through the resources available to me, how I’ll keep records, and the pathways I’ll market through, the network has allowed me to identify gaps in my knowledge and provided information and guidance to help fill them.

— Gillian Trimber, Geneva NY

The project has been most helpful in budgeting, sourcing materials, and logistics of beginning shiitake cultivation. The resources and extension support via Cornell Small Farms, specifically the budget information provided in the information packet (and pdf version) as well as the supplier page of the Cornell Mushroom website were vital. Having a one-on-one phone call forced us to get our plans solidified and helped us identify our pain or struggle points in advance. Having the email network to fall back on is also a great support and educational source. We feel prepared to bring our mushrooms to market next season because we have specific steps to take in order to properly market our product.

- Marni Duffy, Zera Farm

After attending the workshop I was inspired to make shiitake cultivation a larger part of my farm business plan. There was still snow on the ground so I was able to harvest and inoculate 400 bolts before the end of April. The business planning help was also very useful for me. I used a budget template that Steve provided in the workshop to set a goal and plan for the next three to four years. Later in the fall, Steve came to visit the site as part of a workshop for other local growers and those interested in shiitake growing. We walked in the woods and visited the laying yard and barn where I am cultivating mushrooms. The feedback I received from participants, the extension agents, and other shiitake growers was very helpful towards improving and streamlining my current systems.

- Josh Smith, Black Kettle Farm, Essex, NY

We are in our first year of sales and next year will be double. Our goal is to be completely self-employed within five years only doing what we love. Thus growing our local community and promoting small businesses in the area.

— Chris Flickenger