Enterprise Viability

Forest owners and farmers interested in producing shiitake mushrooms as a new enterprise should develop an Enterprise Assessment to analyze opportunities, examine competition, clarify resources and project expenses needed prior to making a firm commitment to proceed with the new venture.

An Enterprise Assessment can assist us to project economic impacts from specific management and production changes, in examining alternative markets, in developing value-added products and in analyzing the feasibility of adding shiitakes to an overall farm business. An Enterprise Assessment examines revenue and expenses to be budgeted only in relation to one specific enterprise, rather than analyzing the entire farm or business operation’s income and expenses. A broader assessment can compare the income and expenses for multiple activities involved in diversifying your operation.

In the following pages, we’ve included two enterprise assessments. The first is actual records from a large commercial shiitake enterprise (Green Heron Growers). The second is an estimate of what expenses and profits a farmer could expect beginning a smaller shiitake enterprise; the values in this estimate were based on data collected from 14 beginning shiitake farmers in the Northeast. Lastly, we’ve included a blank spreadsheet to help guide you in completing your own Enterprise Assessment.

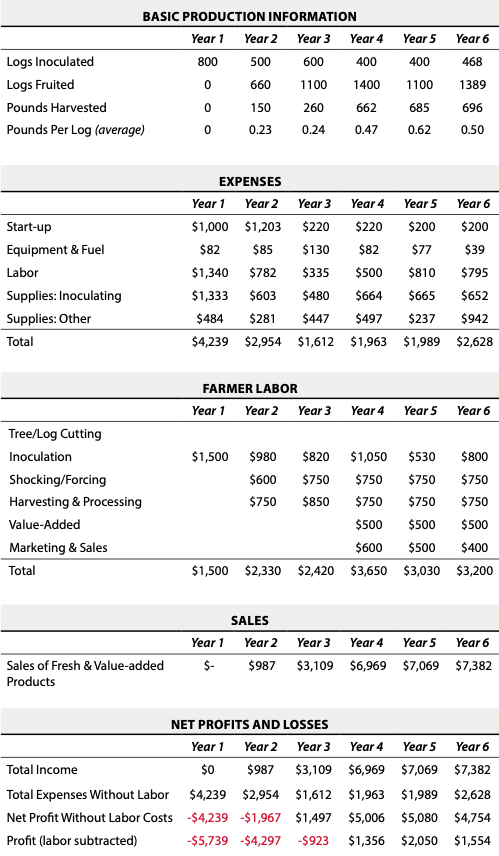

Scenario 1: Large Commercial Production

Between 400 and 800 logs inoculated per year with over 2,000 logs in rotation

The following data was gathered by one thriving shiitake enterprise, Green Heron Growers. It is intended to show how much a well-organized and dedicated grower can expect to make, if working with a large number of logs.

Labor cost projections were made assuming an hourly wage of $10 was paid to everyone working on the project.

The first profits were generated the third year.

EXPERT TIPS: Putting Profits into Prospective

Don’t be scared off as you look at the slow and expensive start our shiitake operation had. We started out using red maple logs the first two years and did not have great results. Because you never know how the logs will produce till the second year, we went ahead with red maple again the second year, because that was what we had on our land. Best thing about this was the reduction of this low quality tree in our woodlot! On top of that, we inoculated with CW, WR and WW strains the first year and mostly WW the second year because it was recommended by the supplier for red maple.

We were not impressed. Harvests seemed good to us as newbies, but when our Cornell friends said to expect close to a pound a year/log we know something needed to change. The third year got oak logs from nearby state lands and used mostly WR & CW. Since then we’re begun harvesting sugar maple and beech from our land one year and then oak from off site the next year.

Our high start-up expenses also make this enterprise not look all that “viable”. The perfect location for our shiitake yard is very far from our house. It was the only hemlock grove that wasn’t in a swamp, so we had to make it accessible by building a section of gravel road. The need for water also required investments. Labor for inoculating was another high cost, but we’ve gotten better at creating workshops and volunteer opportunities to get that done.

So we’ve learned a lot and enjoy our shiitake experience immensely. Year 7 our income rose to $9,000 and costs remained much the same. We wouldn’t want to stop now!

- Steve and Julie Rockcastle, Green Heron Growers

Scenario 2: Small 100-Log Operation

100 Logs Inoculated each year for 5 years

In 2011, 21 aspiring shiitake mushroom growers inoculated 100 logs with shiitake spawn. Over the course of the next two years, growers kept detailed records of their labor, expenses, production and sales. Using their data, we’ve estimated the expenses and income one could expect during the first five years of a small shiitake commercial shiitake production operation.

The assumptions used to generate each analysis are listed to the left of each table. Keep in mind that these values are averages (means) and that there was substantial variation between growers. Where appropriate, we’ve included a chart illustrating the range.

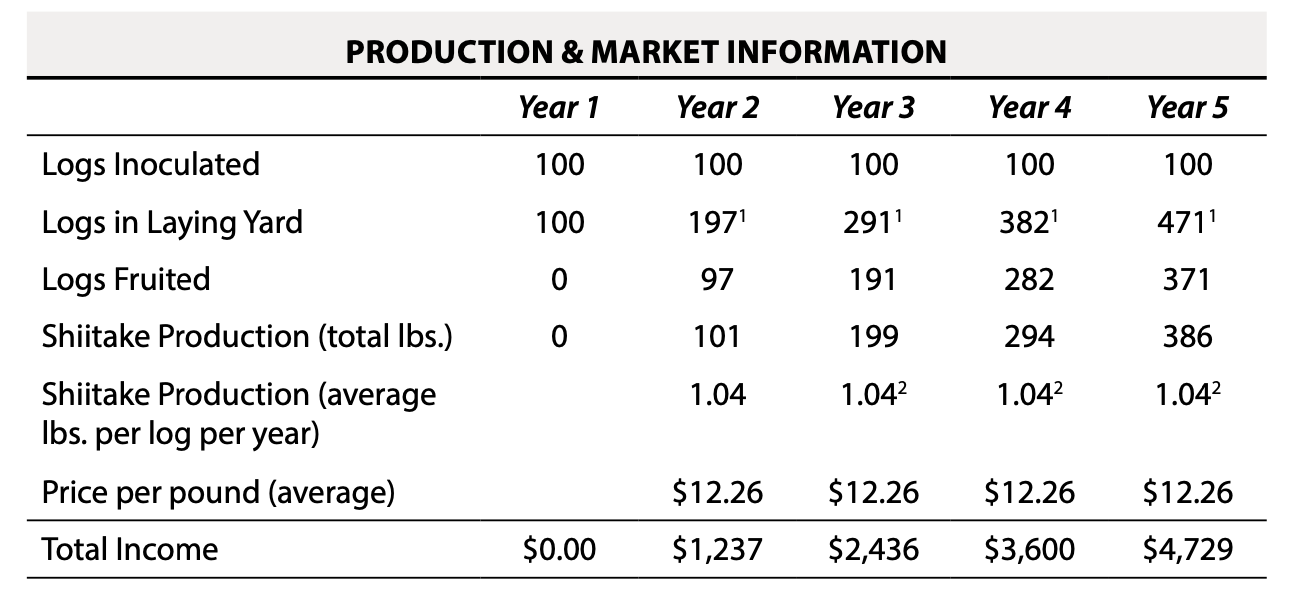

Product and Market Information

This estimate assumes that growers inoculate 100 logs per year for five years. Beginning farmers in the study produced approximately 1 pound of mushrooms from each log during the study’s second year. Farmers sold their mushrooms for about $12 per pound (on average), predominately to restaurants and at farmers markets. Through these sales, they were able to generate roughly $1,237 during the second year; if these trends continue, they could expect to generate nearly $5000 per year during the fifth year of the operation when 371 logs would be actively fruited.

1. Value assumes that 3% of logs are culled each year as a result of bark, insect and/or competitive fungal damage.

2. Assumes that logs produce, on average, the same amount of mushrooms each year, over their lifetime. in reality, production will peak during the third year and be highly variable depending on a wide range of factors (see “EXPERT TIPS: what yields to expect and how to improve yields” on page 37).

The weight of mushrooms produced by a single log varied substantially among growers depending on the species of tree they used, timing of inoculation and general management scheme. There are a variety of explanations. In this study, we observed growers who spent more time working on their operation had better-producing logs, likely because they took better care of the logs. In addition, growers that used oak and maple realized higher yields than growers using other tree species. Lastly, logs inoculated soon after the trees were felled yielded more mushrooms. For more information about yield per log, see Expert Tip on page 37.

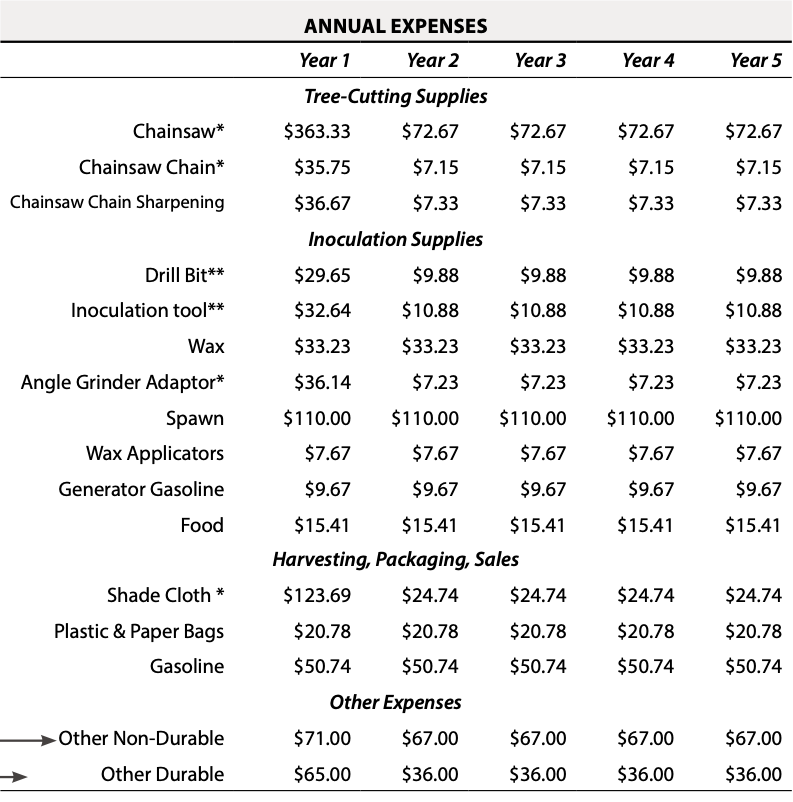

Annual Expenses

There are many ways to calculate operation expenses. Below we’ve listed the items most commonly purchased, and the average amount participants spent on each item. We also listed the average amount that participants spent on other durable and non-durable expenses during years one and two.

For certain durable items, such as a chainsaw, we’ve also assumed that these items will need to be replaced every three to five years (depending on the item). To account for this upcoming cost, we’ve amortized the cost of the items over the years preceding their purchase. In other words, money is put aside each year to save up the future purchase of big-ticket items based on how long the item is expected to last.

Using these assumptions, we find that the cost to start a small shiitake operation is approximately $1,000. Keep in mind that for many landowners who already own items like a chainsaw, angle grinder and shade cloth, the up-front costs will be much lower. Ongoing cost total roughly $500 per year.

*Items are replaced every 5 years. Cost of repurchase amortized over 5 years.

**Items are replaced every 3 years. Cost of repurchase amortized over 3 years.

Other non-durable expenses

Includes business cards, chainsaw repairs, flagging tapes, labels, organic certification fee, propane, shipping expenses, spread ingredients, tent and tractor rentals

Other durable expenses

Includes building materials, extension cords, baskets, generators, gravel hoses, safety equipment, scales, signs, stoves, tables, tents, water tanks, and wax pots

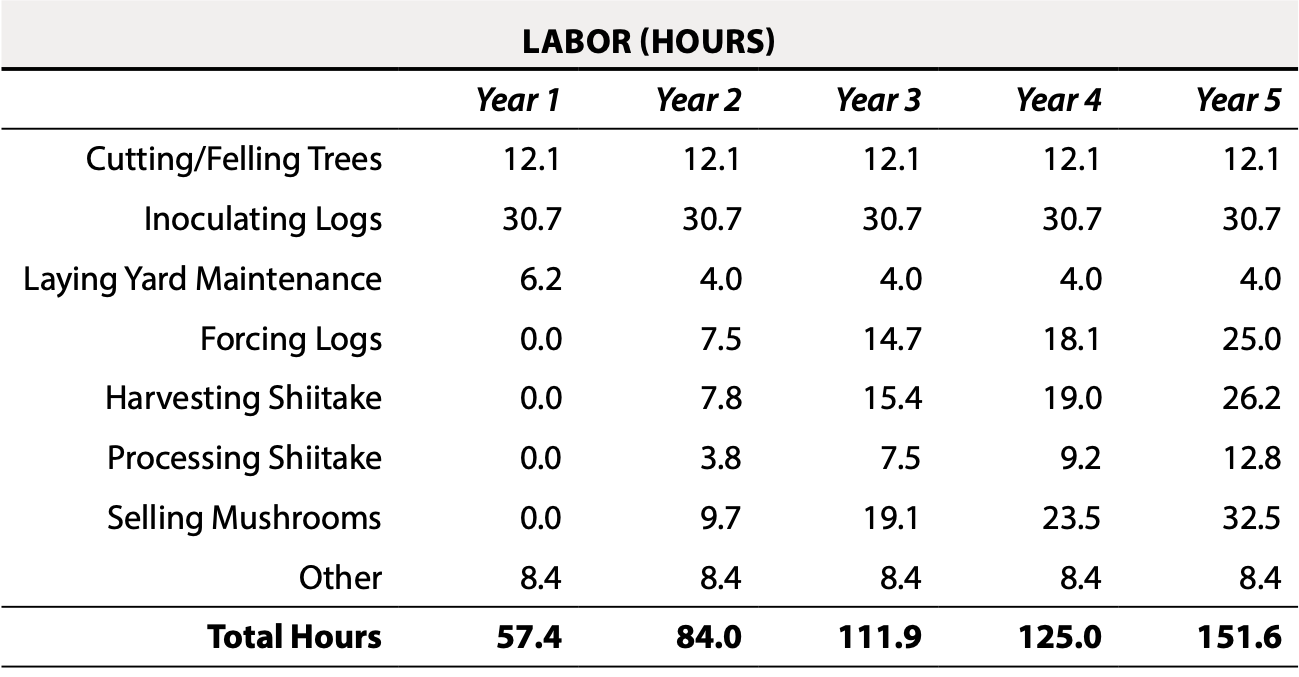

Labor

Participants in the research project recorded how much time they spent performing various activities related to their shiitake mushroom operation. We’ve compiled the data in the table below. In order to project beyond the two-year span of this project, we’ve also made the assumption that, for certain activities like forcing logs, and harvesting processing and selling mushrooms, the amount of time required will increase proportionally to the number of logs in rotation.

During the first year, expect to spend about 60 hours on shiitake mushroom production related activities. The number of hours necessary will increase as the number of logs handled increases.

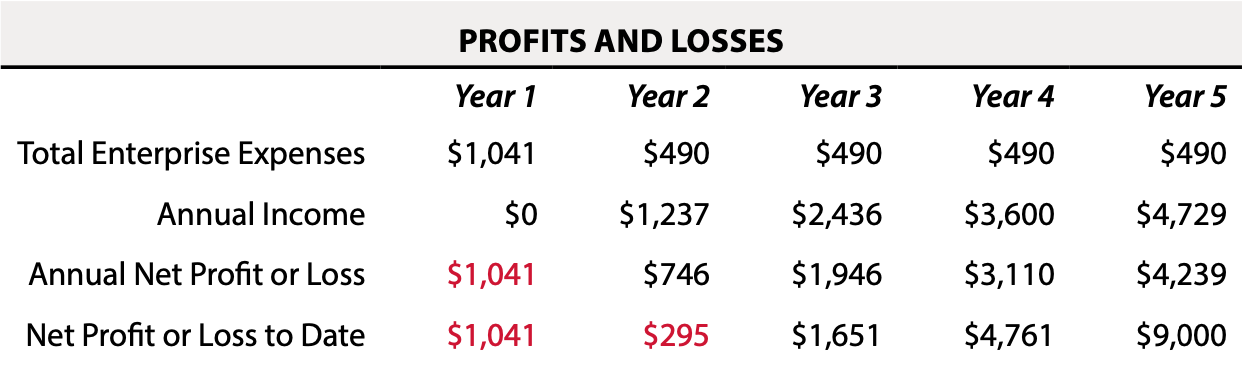

Profits and Losses

Using the data from the “Annual Expenses” and “Production and Market Information” we can calculate expected profits/losses for each year of the shiitake operation. In the table below, “Annual Net Profit and Loss” is the profit/ loss from a single year. “Net Profit or Loss to Date” is the sum of the profits and losses from the preceding years; in other words, it is the total amount generated or loss during the enterprise’s duration.

Based on the data from the 13 farmers in this project, and using the assumption described above, one small shiitake mushroom operation could be expected to generate $9,000 in over five years. It would take three years to recoup the operation’s startup costs.

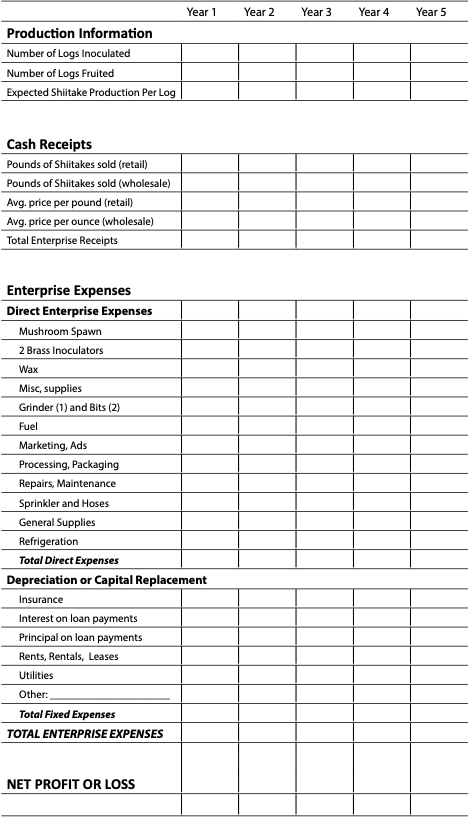

Create your own enterprise assessment

Direct enterprise expenses are ONLY income and expenses explicitly for this enterprise.

To include what you will have to pay whether you have this enterprise or not - as a share for this enterprise - put them under fixed/overhead expenses.