Section 1: Post Harvest Handling

A. Safety & Sanitation

The most important detail in the post-production aspect of shiitake production is to maintain a high quality and safe product for sale.

Mushrooms, in particular, are unique in that they are mostly water, and are not best cleaned by washing, since it ruins their texture and shelf life of the product.

For this reason, it is CRITICAL to ensure that mushrooms are carefully handled during all phases of harvesting through selling.

For fresh, uncut produce, no licenses are required to sell specialty mushrooms in New York.

This doesn't mean that one should not carefully follow best practices to ensure the product is safe.

Additionally, as you scale and depending on markets you want to sell to, you may be required to adhere to produce safety programs, described below.

Sanitation Checklist

What is the different between the FSMA Produce Safety Rule and GAPS?

Some farms may now be required to comply with the Produce Safety Rule as part of the implementation of the Food Safety Modernization Act (FSMA).

A FSMA PSR INSPECTION An inspection is a mandatory review of a farm’s food safety practices to confirm compliance with the FSMA PSR. An inspection is a review of all covered crops and covered activities on a farm, and is conducted by either an FDA or state agency official, depending on the state.

A GAPS Audit is a voluntary review of a farm’s food safety practices to confirm compliance with the audit’s produce safety standards. Produce buyers may ask their supplying farms to pass an audit as a purchasing requirement.

Produce Safety Rule

Some farms may now be required to comply with the Produce Safety Rule as part of the implementation of the Food Safety Modernization Act (FSMA).

Farms grossing between $25,000 and $250,000 in sales will need to comply, unless a farm is “qualified exempt” which is defined as a farm that:

1. Has a three-year running average gross revenue of less than $500,000 in sales

2. Sells the majority of the food to “qualified end users”. That means either direct consumers of the food, or retail locations within 275 miles of the primary address of the farm.

If you meet these, you are “qualified exempt”, but still must comply with labeling and record keeping measures.

Good Agricultural Practices (GAPS)

The GAPS is a voluntary food safety monitoring protocol. Some markets (such as larer grocery chains) may require GAPs in order to sell to them.

Further, if you want to enroll in the New York State Grown & Certified Program, you must be a GAP certified farm. https://certified.ny.gov/

Regardless if you are required to comply or not, it is your responsibility to prevent contamination of produce and water supplies, follow good sanitation practices, avoid introducing raw manure into production systems, test irrigation and wash water for bacteria, and maintain good records.

For information consult: www.gaps.cornell.edu or call 315-787-2625.

Familiarize yourself with standards for the Mushroom GAPS Program (NOTE: these are developed specifically for button mushrooms grown in composted manure, not directly applicable to many specialty mushroom enterprises):

https://www.ams.usda.gov/sites/default/files/media/fresh%20mushroom%20food%20safety%20standards.pdf

GAPS Checklist for Mushroom Farms: https://www.ams.usda.gov/sites/default/files/media/mGAPVersion2.pdf

A Mushroom Farm Food Safety and Security Self-Assessment document from Penn State is a helpful reference to see how your farm stacks up in terms of the GAP standards:

Production Practice Certifications

In addition to the food safety programs above, you may wish to consider certifications that provide guidance and standards for production practices:

Certified Organic offers national standards for mushroom production according to organic practices. See the USDA standards and a helpful factsheet from NOFA-VT for the details.

Certified Naturally Grown (CNG) offers peer-review certification to farmers and beekeepers producing food for their local communities by working in harmony with nature, without relying on synthetic chemicals or GMOs. They have a published list of standards for mushroom production that offer great guidelines and detail into keeping your product safe. www.cngfarming.org/mushroom_standards

New York State Grown & Certified Program, must be a GAP certified farm. https://certified.ny.gov/

Mushroom Harvesting and COVID-19

White the virus is NOT a food borne illness, and there is very low risk of transmission through mushrooms, its important to double down on safety protocols. In addition to following standard food safety protocols it is good to take further measures to reduce any risk for products or customers.

According to USDA:

"We are not aware of any reports at this time of human illnesses that suggest COVID-19 can be transmitted by food or food packaging. However, it is always important to follow good hygiene practices (i.e., wash hands and surfaces often, separate raw meat from other foods, cook to the right temperature, and refrigerate foods promptly) when handling or preparing foods." https://www.usda.gov/coronavirus

Best practices:

-

All owners and employees must wear a face cloth or protective face mask for tasks where two or more people cannot easily maintain a minimum of 6ft distance. Whenever possible, one person will do a task in smaller spaces rather than two. Anyone experiencing any sick symptoms must report and will stay home from work.

-

Any mushrooms are harvested and handled with gloves and face mask, especially given they are not washed as part of the process.

-

Advise that customers can wipe mushrooms with a damp cloth with light food grade disinfectant (such as vodka or gin) if they so choose. All mushrooms should be cooked on medium heat for at least 5 min before consuming.

-

HAND WASHING with hot water, soap, and sanitizer must take place by all employees and farm owners between all transitions (before and after) of any farm tasks.

B. Harvesting, Cleaning & Storing Mushrooms

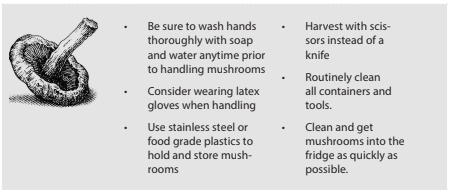

Mushrooms should be harvested directly into clean stainless or food grade plastic containers, which should be washed and dried thoroughly before use. All harvesters should wash their hands with warm water and soap before heading out to harvest. An alternative option would be for everyone to wear food grade latex or vinyl gloves when harvesting.

The proper timing of harvest is critical to achieving a quality crop that will last. While it is tempting to let the mushrooms get as large as possible, what is more important is the integrity of the mushrooms to hold up to storage and transport before being consumed. The difference is considerable; an overripe mushroom (left) may only last a few days in the fridge, whereas mushrooms harvested at the proper time (right) can last a week or more.

Harvest when the cap is mostly unfurled, but not flat. With time and experience, you will notice that the rounded caps are more robust, and will retain their color better. It’s important to note that specialty mushrooms at all stages of development are edible, and inevitably a grower will not get all of them harvested at the perfect stage. Overripe mushrooms may be perfectly fine for some outlets, or can be reserved for dehydration or other value-added products, discussed later in this guide.

Since the edge of the mushroom is not always obvious from above, growers often check the edge with their pinky to see if it’s ready. Mushrooms that are ready for harvest should be carefully cut at the base with scissors or a knife, or pulled or twisted off.

During the harvesting process, if a harvester comes into contact with a potential contaminant, or cuts themselves, they should immediately stop harvesting and clean and cover their hands prior to resuming harvesting.

Many growers find that it’s worth the time to sort mushrooms during harvest. Depending on markets, some sort by size, as some outlets prefer more uniform shiitake of a specific size. For example, many restaurants like smaller mushrooms that can be directly added to dishes without slicing, whereas others want to slice them, and prefer the mushrooms as large as possible. Learning these details are part of the task of good marketing at outreach efforts to your customers.

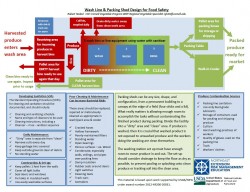

Food Safety Considerations and Design for Packing Sheds

from the Cornell Vegetable Program

Last Modified: February 16, 2015

This diagram, showing food safety considerations and design recommendations for packing sheds, is not intended to give actual dimensions and square footage since packing sheds can be any size, shape, and configuration. It can be as formal as a permanent building or a canopy at the edge of a field (four sticks and a lid).

What really matters is allowing enough room to accomplish the tasks without spreading contamination into the finished product during packing. If produce washing is done, then it is crucial that unwashed product doesn't come into contact with washed produce and the workers doing the washing are clean themselves.

The washing station set up needs to have enough room to move produce in and out. The equipment set-up should consider good drainage to keep the floor as dry as possible, no pooling, or splashing onto clean produce.

NOTE: The major difference with this diagram with concern to mushrooms is there is not a wash-wash--rinse, but rather a brush or air cleaning as suggested above.

Cleaning

Mushrooms should always be cleaned prior to storage. Due to the high moisture content (90%+), it is not feasible to wash them in water. Instead, a variety of brushes are used to clean them. You can purchase specific “mushroom brushes,” but many types of paintbrushes, available locally at hardware stores, will suffice. It’s worth having several sizes that differ in the hardness of the bristles, as well as the length, to address different cleaning needs.

Additionally, a damp towel can be used to pat mushrooms and clean them lightly, if necessary. For outdoor cultivation, it is also essential to design your laying yard to reduce dirt splash by putting fruiting racks on gravel, woodchips, or elevated off the ground.

Thrips, tiny insects that enjoy getting themselves in between the gills, are commonly found on freshly harvested mushrooms. They don’t tend to damage the mushrooms, but should be immediately removed upon harvest. Gently tap the cap once, wait a second, and tap again. Compressed air can also be used after tapping to help blow them away, being careful not to damage the gills. Using your mouth to blow on them is not a sanitary practice.

Storing

Once mushrooms are clean, they should be stored in food grade containers in refrigeration conditions at 36 – 38 degrees F. Storage bins with loose fitting lids are ideal; never seal the lid on your storage container. These are widely available from restaurant supply stores. Refrigerate forest-grown mushrooms as soon as possible after harvesting. Properly harvested and cleaned mushrooms will remain fresh and marketable for several days.

Make sure that your customer also has the appropriate refrigeration equipment, or if you are selling at a farm market or through a small retailer, that they can store your product adequately.

Mushrooms should never be stored in plastic bags OR containers. Paper bags work well for small amounts.

C. Grading

Though not required, it is recommended for good marketability that mushrooms are graded. There is not an official grading system, but the scale below provides some guidelines based on grower experience:

Grade “A”

- White gills

- Caps curled and rigid

- Remnants of universal veil (white specs)

- No damage or defects

Outlets:

- Retail

- Restaurants, CSA

- Wholesale

Grade “B”

- Minor damage or defects

- Caps flattened or slightly curled

- Duller gill coloration

Outlets:

- Retail

- Restaurants, CSA

- Wholesale

Grade “C”

- Extensive damage or defects

- Harvested well past prime

Outlets:

- Dried

- Value-Added

- Some chefs will buy at steep discount

D. Weighing

BULK (like at a farmers market or grocery store) Bulk displays are not subject to any required grading, labeling or packaging. If selling bulk items by weight an approved scale must be used. The vendor is responsible for purchasing an approved device AND having it certified by a local Weights and Measures official.

Pre-Packaged If selling food items pre-packaged, these need to be accurately marked, with (a) the net weight, standard measure, or numerical count; (b) the selling price per pound or unit of standard measure and (c) the total selling price.

Sell by volume? One option to avoid having to purchase and maintain a certified scale is to sell by volume. For instance, at a farmers market, growers often sell by the pint, which is about 1/4lb. This won't work for any packaged goods for sale. Selling to resturants or through a CSA is an agreement between buyer and seller, not requiring a certified scale but relying on the trust between buyer and seller.

E. Packing & Labeling

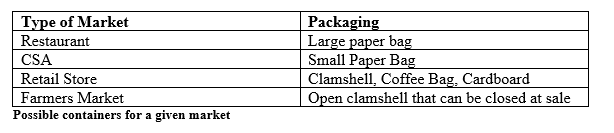

The type of packaging used depends largely on the outlet. Protecting the product, while making it appealing for purchase, is key. Containers should be breathable, and if at a retail outlet, should enable the product to be seen by potential customers. For wholesale outlets, like restaurants or through a weekly CSA, paper bags with a sticker label are sufficient, and keep mushrooms well. The cost of containers, and their environmental impact should also be considered when deciding what to use for packaging.

Labeling The function of a product label is both legally required, and an important marketing tool. Be sure you comply with the law, as well as spend time designing appealing labels before spending money printing them.

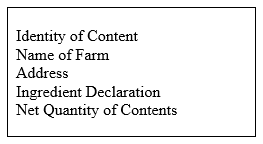

For product labels in New York State, the following items are required:

More detailed information on labeling requirements: http://www.agriculture.ny.gov/fs/pdfs/fsi514.pdf

Your label should be part of your farm “brand” and entice purchases. More of this is discussed in part two if this guide book.

F. Pricing

The pricing one can get for their product is not fixed, but rather relative to the demand for a product, the value a customer assigns to it, and the effect of other competitors on the market. The price is also different for retail versus wholesale outlets.

Retail sales are in smaller quantities (1/4 to 1 lb), direct to the end-consumer.

Wholesale sales are in bulk (3 - 5+ lbs) and usually to an entity that will then resell them to a consumer, like a grocery store or restaurant.

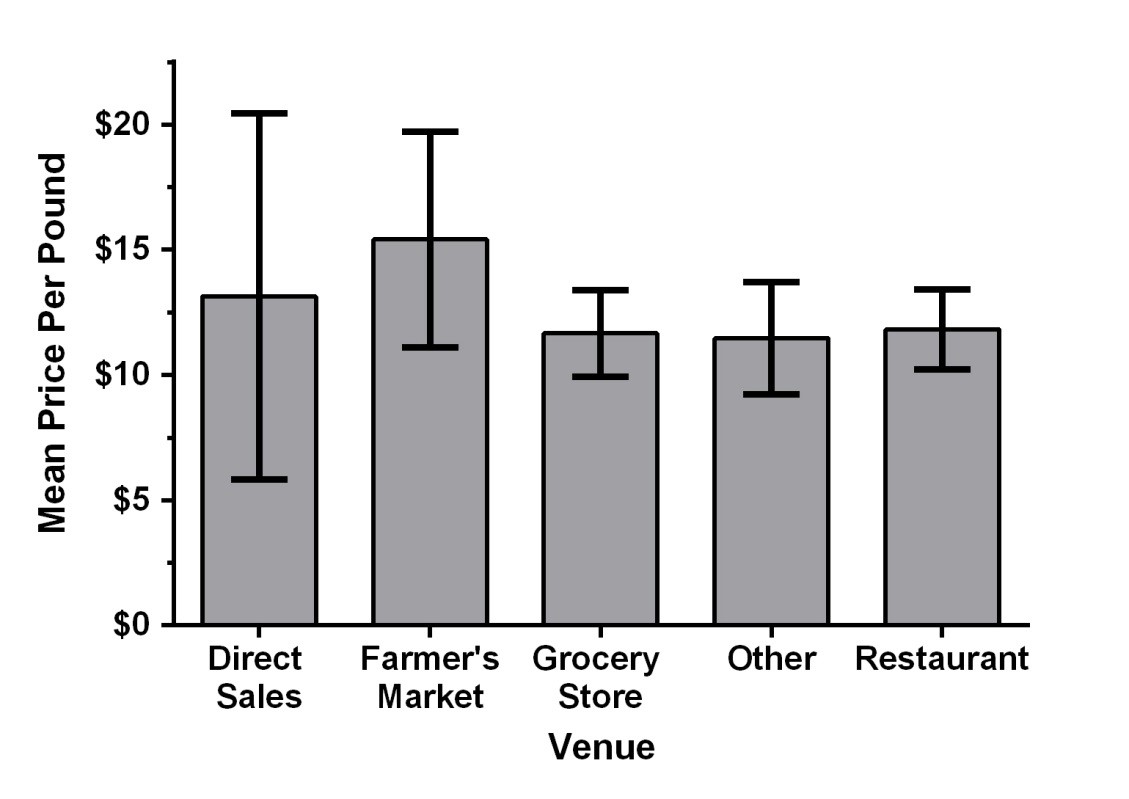

Data from farmers selling log-grown shiitake around the Northeast from 2010 – 2012 shows average prices of $10 – 12/lb wholesale, and $12 – 16 retail. (chart at left)

Pricing is NOT only a function of what you think someone will pay, but also about ensuring your costs and goals are being met.

This distinction is often overlooked by farmers, and pricing should be determined from thorough enterprise budgeting. (see section two)

The Many Faces of Pricing There are many ways to articulate your price to you customer, and some will be more enticing. For example, specialty mushrooms could be sold for $16 per pound in a range of approaches:

A $4/pint container at a local farmers market (1 pint= about 1/4 lb)

As $8/week for 1/2 lb share in a Community Supported Agriculture model.

As $5 per package as a local foods co-op (with.35 lbs per package)